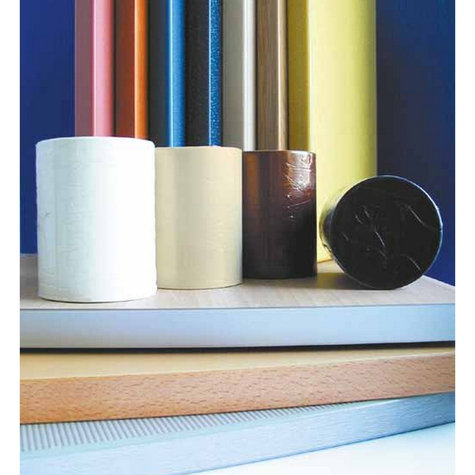

KLEIBERIT 782 SUPRAMELT SLUG 15.6KG IVORY

Quantity

UNIT OF MEASURE: 1 = 1 Each

UNIT OF MEASURE: 1 = 1 null

Recommended Uses

- Bonding of Epoxy resin edges

- pre-primered abs edges

- solid wood edges

Features

- Protected from dust

- Problem free melting

- Increased melting speed

- easy change of cartidges

- The easy slide coating doe note need to be removed prior to processing

- Pre heat time 2-5 Mins

Advantages of the easy slide coating:

• Protected from dust

The cartridge is protected from contamination, dust and dirt whilst being stored at the work place. In addition to this even if stored in a warm environment the cartridges do not stick together.

• Problem free melting

The new foil coating acts like a lubricant when in the machine. It aids smooth problem free melt rate and dissolves without trace during the melting process.

• Increased melting speed

The cartridge with the easy slide coasting ensures increased melting speed, which is required to bond wide edges and long substrates.

• Easy change of cartridges

When colour changes are required, the cartridges can be taken out and used again easily, as the foil protects the cartridge.

APPLICATION

• Both substrates have to be cut to an exact right angle and must be free from dust.

• Bring the substrate and the edging material up to room temperature

• The ideal moisture content of the wood is 8 - 10%, room temperature of min. 18 °C, avoid drafts

• Pre heat time 2 - 5 minutes, application temperature 200 - 220 °C

• Correct temperature settings are especially important when bonding solid wood edges

• When bonding long and/or ridged pieces the application temperature should be in the higher temperature areas.

• Lower temperatures reduce the „wetting out” of the edges

• Coat weight and press pressure should be adjusted so that the applied beads are pressed flat and the adhesives quills out on the edges slightly. To determine the correct coat weight the use of a transparent edge is advised.

TECHNICAL PROPERTIES

• Basis Ethylene-Vinylacetate-Copolymer

• Specific gravity approx. 1.3 g/cm³

• Softening point (Ring and Ball) DIN 1995

120 °C ± 10 °C

• Melting index DIN 53 735 (MFI 150/2.16)

60 c 15 g/10 min.

• Pre heat time 2 - 5 minutes

• Speed 8 - 20 m/min.,

depending on machine

• Heat resistance to +80 °C depending on edge

• Cold resistance to -20 °C depending on edge

• Colours white (10)

ivory (20)

mahogany (70)

black (99)

• Packaging cartridge

Ø: 63 ± 0,5 mm

length: 80 ± 2,0 mm

NOTE

• For solid wood edging the use of linear grain wood is preferable as this is less prone to bend.

• To achieve optimum bond strength the wood grain of the edges should be vertical on the bond surface.

• Precisely align the edging material

• The chipboard should have a surface which does not have rough cutting marks.

• The easy slide coating does not need to be removed prior to processing.

CLEANING

When cleaning the application equipment observe the manufacturers

instructions.

DISPOSAL

Hardened adhesive domestic waste disposal

Our packaging is made from recyclable materials.

PACKING SIZES

Carton with 45 cartridges, approx. 15 kg net.

STORAGE

KLEIBERIT 782 Supramelt

Can be stored for approx. 2 years

Store cool, dry and in original sealed packaging.

Product Attributes

| UOM Information |

1 = 1 Each |

| Kit | No |

| Colour | Ivory |

| Material | ETHYLENE |

| Supplier Code | 782.0.2009 |

Warranty

| Length | 730 days |

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null

UOM: 1 = 1 Each

UOM: 1 = 1 null