KLEIBERIT 782.5 SUPRAMELT SLUG 11.3KG CLEAR

Quantity

Pack size = 1 Each

Description

Fields of application

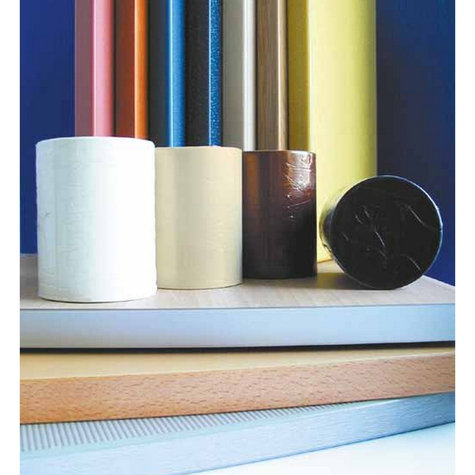

Edging of sheet material with:

• ABS-, PMMA-, PVC- and PP-edges (with suitable bonding agent)

• Paper-edges

• Veneer and solid wood edges

Advantages

• Delivered in cartridges with protection film and granulates

Properties of the bond

• Heat resistance approx. 100°C according to the edge (the bond withstands temperatures of up to 120°c in a drying tunnel for a short period)

• Cold resistance according to the edge down to approx. -30°C

• Good resistance to water (important when staining or bleaching veneer edges)

• Good ageing resistance

Properties of the adhesive

Base: EVA Copolymer

Specific gravity: approx. 0.96 g/cm3

Colour: transparent yellowish

Viscosity

Brookfield HBTD, Sp. 27/10 rpm: at 200°c: approx. 36,000mPa·s

Melting index according to DIN 53 735

{MFI 150/2,16): approx. 105 g/10 min

Softening point {ring + ball): approx. 101 °C

Melting time: 2-5 min

Working temperature:

Above 200°c. For solid edges or difficult plastic edges up to 230°C (short period only).

Low temperatures can cause faulty bonding - ensure that the temperature is correctly set.

Delivery form: 1. Cartridge 0 63 ± 0.5 mm Length 80 ± 2 mm 2. Granulate

Identification: Identification not required according to EU regulations (see our safety data sheet)

When hotmelt adhesives are melted and applied, vapours are set free and an unpleasant odour can occur even if the recommended working temperature has been observed. Moreover, if the prescribed working temperature is exceeded over a longer period, harmful decomposition products can develop. Precautions should be taken to eliminate the vapours, e.g. by using a suitable ventilation system.

Feed rate

• Depending on edging material between 18 - 35 m/min. Different speeds are possible depending on installation equipment.

Processing

The substrates for edge bonding have to be processed at exact right angles and should be free from dust. Boards and edges have to be conditioned to room temperature. The most favorable moisture content of the wood is 8-10%. Room temperature should not be lower than 18°C. Draughts have to be avoided.

Melting time: 2 - 5 min

Working temperature: above 200°C

When processing wood types which are difficult to bond, the working temperature can be briefly raised

to 230°C.

Temperature control is particularly important when bonding solid wood edges. For long and thick items, work within the higher temperature range.

Lower temperatures lessen the wetting of the edge. The amount of adhesive and pressure applied should be set so that the beads applied are squeezed to form an adhesive layer all-over the surface to be bond and the adhesive pearls slightly at the edge. This can be checked best with a transparent test edge.

Tips for solid wood bonding:

• For solid wood edges select plain, mature wood which does not tend to sag

• Wood edges with standing year rings for the glue line provide optimal strength

• Prepare the carrier material carefully

• Chipboard should not have any rough cut surfaces

• Adjust the press rollers to somewhat less than the edge thickness.

Further processing:

The finished material can be processed further immediately following bonding

(Sawed, milled, planed, etc.).

Because the characterisics of edging materials can vary, individual testing is essential!

Cleaning

Observe the manufacturer's recommendations when cleaning tools and application plant.

Packaging

KLEIBERIT SK 782.5:Delivery carton with 45 cartridges, approx. 11 kg Paper bag, 20 kg net

Storage

KLEIBERIT 782.5 Supramelt can be stored for

2 years. Keep cool and dry.

Recommended Uses

- Bonding of Epoxy resin edges

Features

- Protected from dust

- Problem free melting

- Increased melting speed

- easy change of cartidges

- The easy slide coating doe note need to be removed prior to processing

- Pre heat time 2-5 Mins

Attributes

Product Attributes

|

UOM Information

|

1 = 1 Each |

|

Kit

|

No |

|

Brand Name

|

Kleiberit |

|

Colour

|

Clear |

|

Material

|

ETHYLENE |

|

Supplier Code

|

782.5.0011 |

|

Supplier Item Code

|

7112555 |

Specifications

Warranty

|

Length

|

730 days |

Variants

|

Colour

|

Clear |